Installation

Gatco Anti-Friction Rotary Bushings are furnished with .020 grind stock on the O.D. of the outer case to permit selective fitting. (Finish ground O.D.'s are available at extra cost).

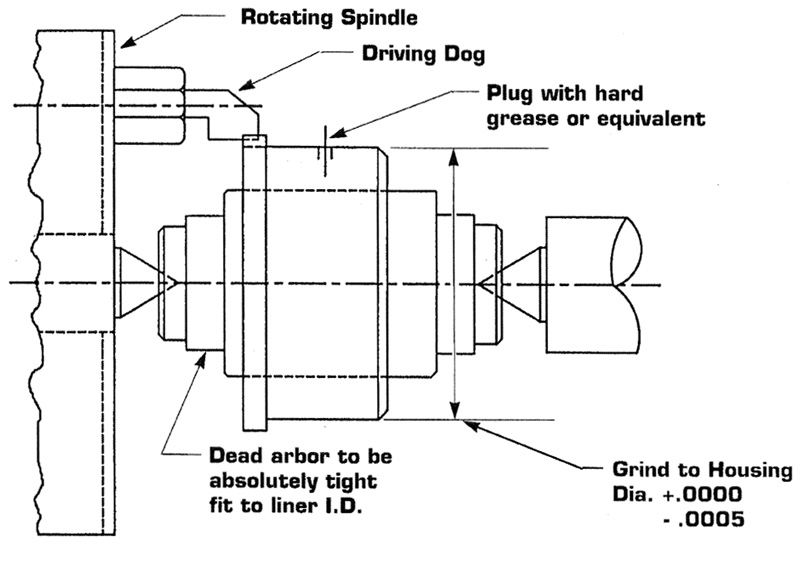

The figure shows the simple grinding procedure necessary prior to installation. As illustrated, an arbor must be ground for an absolutely tight, or light press fit to the I.D. of the rotary bushing liner and, with the rotary bushing, is mounted between centers. A drive dog, attached to the machine spindle, is engaged in the manufacturing slot provided in the flange of the outer case.

The lubrication hole (for those models with a hole and not a fitting) should be plugged with hard grease. By leaving the arbor "dead" and rotating the outer case with the drive dog, the case O.D. is then ground concentric with the liner I.D. to size determined by the existing or specified housing bore (refer to the figure). An offset clamp may be required at final installation to retain the bushing in the bushing plate.

Sizes GN/N/GNM/NM-500 through GN/N/GNM/NM-1375 have one bearing only, which permits the liner to cant slightly as the rollers are crowned. Live arbor grinding is necessary. When O.D. grinding, follow the above procedure, except drive the arbor and inner liner with the outer case. The inner liner must be locked up to prevent radial movement during grinding. Because the rollers are crowned, I.D. runout must be checked in the center of the needle bearing, at approximately the 2/3 point inside the bushing I.D. from the flange end.

Contact Gatco for O.D. grind procedures.

NOTE: Grind underside of flange when O.D. grinding to insure O.D. & shoulder are square.